Home / News

The selection and comparison of magnetic cores, powder cores, sendust cores, and ferrites is a question that engineers often discuss in the question of high-power inductive core selection. The core selection of high-power inductors in the shopping mall is still quite a lot. The available inductor materials are: sendust cores, iron powder core, iron silicon (silicon steel lamination), void ferrite, molybdenum moiré and high magnetic Wait.

Sendust Cores and void ferrite

Sendust Cores and void ferrite are commonly used raw materials for two ferrosilicon powder cores. In terms of softness and fullness, the void ferrite must be planned in the safe zone of the falling curve. The iron-silicon is planned to be within the range of the controlled descent curve, so that the fault-tolerant characteristics can be supplied, especially at high power hours.

In terms of magnetic flux comparison, a specific 50% reduction planning point is set. The magnetic flux of Sendust Cores is more than twice that of the void ferrite, which can reduce the scale of the magnetic core by 35%, and the scale of the magnetic core can be reduced during planning. 30% to 35% smaller.

The soft full curve makes the iron-silicon plan itself fault-tolerant, while the void ferrite does not.

Ferrite flux can be changed with temperature, while iron-silicon is relatively stable. Many ferrite suppliers may give the difference in raw materials in different environments from 25% °C to 100% °C. Since the raw materials and results of the Sendust Cores are different from those of the void ferrite, the change will not be much followed by the temperature change.

In terms of marginal loss, iron-silicon does not cause marginal loss, and void ferrite has a large marginal loss. Some of the voids in the core are added along with the added loss of temperature. KoolMμ also has voids, but this is a uniform distributed void, which is very good for high power applications.

Regarding the scale and energy storage, it can be seen from the comparison of the iron-alumina (KoolMμ) and the Mn-Zn ferrite in the LI2 value that when the scale is 55mm, the test Sendust Cores is 60μ, and the Sendust Cores (KoolMμ) is In the case of a small volume, the energy storage is about twice that of manganese-zinc-iron ferrite. When the energy storage is the same, the LI2 value is the same, and the volume of KoolMμ is much reduced. For the planner, this is useful to reduce the planning scale.

The void ferrite also has many advantages, the void ferrite can have a very high useful magnetic permeability μeff, the ferrite can be above 500 and the ferrosilicon is now limited to μeff=125. Void ferrites are more suitable for use in some low power planning.

Sendust Cores and iron powder core

In addition to accepting DC bias, switching regulator inductors also have a certain AC current, usually between 10kHz and 300kHz. This alternating current generates a high frequency magnetic field that creates core losses and causes the core to heat up. This situation is reduced in the KoolMμ, so the inductor is more useful and the temperature is lower.

The core loss of KoolMμ is lower than that of the iron powder core. Regarding the magnetoelasticity problem of near zero, KoolMμ is very suitable for eliminating the audible noise in the filter inductor. KoolMμ is not used in the production of organic binders, so there is no doubt about heat aging. All the Sendust Cores (KoolMμ) cores can be operated continuously at 200 ° C. In contrast, the iron powder core is magnetoelastic.

Sendust Cores and ferrosilicon

Special grade ferrosilicon laminations are also used in large inductors, usually in the form of blocks or strips. The advantage of ferrosilicon is that the full magnetic flux density is high. Ferrosilicon shapes (cores of type E, U, and I) can also be applied to large inductors with proper construction. Although ferrosilicon has a higher full magnetic flux density, ferrosilicon has more advantages, such as better softness, low core loss, temperature stability, and lower cost.

The ferrosilicon block has discrete voids that are not the same as the distributed voids of KoolMμ, so it is much faster to follow the current addition. KoolMμ uses the strength of the full curve to plan for smaller inductors.

Characteristics and application of Sendust Cores

Ferrosilicone is composed of aluminum-silicon-iron, which has a fairly high Bmax (1050tM). Its core loss is much lower than that of iron powder core and high magnetic flux. It has low magnetoelasticity (low noise) and is low. The energy storage data of the capital, without heat aging, can be used to replace the iron powder core, and the function is very stable at high temperature.

Ferrosilicon applications include power factor correction chokes, step-up/step-down regulators, DC output inductors and return transformers.

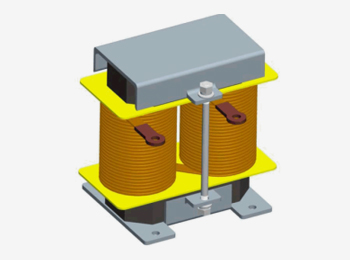

Large Sendust Cores KoolMμ is used in high current (power) inductors, solar energy conversion, UPS uninterruptible power systems, hybrid cars, wind energy conversion and other high current applications.

There are two choices for flat-plate Sendust Cores, with traditional square and round shapes.

Relatively square, round has many advantages, such as reducing the volume of all inductors added by winding, reducing the length of the winding line under the same number of turns, minimizing DCR (DC resistance), dropping copper Loss, drop the cost of using copper wire and the cost of all inductors.

The characteristics of Sendust Cores (flat-plate type) are applied to high-current planning, magnetic flux leakage is reduced to very low, better DC bias characteristics, excellent heat dissipation and temperature stability, and high energy storage energy. Installed on the PCB. The use of KoolMμ (flat type) is used in DC/DC converters, high current chokes, and central processing units in computers.

Mirrack (Guangdong) Micro Metal Magnet Tech. Co., Ltd. is a hi-tech company specializing in R&D & manufacturing of high quality alloy powder cores, as well as a solution provider for a variety of magnetics applications. Email: danny@mirrack.com

What are the advantages of sendust cores?

November 29, 2018

Loss Reduction of Output Inductor for Power Supply

December 05, 2018

Cost Reduction of PFC Inductor for Power Supply

December 05, 2018

Noise Resolution of Inductor for Inverter

December 05, 2018