Home / News

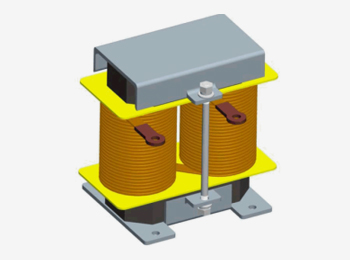

Although ferrosilicon has a higher saturation flux density, ferrosilicon has more advantages such as better soft saturation, low core loss, temperature stability, and lower cost. When the inductor use sendust cores, the disadvantages caused by the use of the void ferrite magnetic ring can be eliminated.

1. The magnetic flux density of the ferrite is equal to or less than 0.5T, which is less than half of that of the ferrosilicon alloy. Therefore, under equal volume, ferrite storage energy is also lower than that of iron-silicon aluminum alloy.

2. In addition, the full magnetic flux density of the ferrite is greatly reduced under high temperature conditions, while the high temperature condition has no significant effect on the ferrosilicon.

3. The ferrite data has the characteristics of fast and full. If the safe current value is exceeded, the integral function of the inductor may be formed, and the iron-silicon-aluminum data has soft fullness and can withstand higher current values.

4. The air gap diffusion margin loss in the open air gap ferrite inductor is very severe, and the problem is not found in the iron silicon aluminum material.

5. The iron silicon aluminum core is very suitable for the energy storage filter inductor in the switching power supply. A 10,500 Gauss fullness ferrosilicon core provides a higher energy storage capacity than a void or ferrite core of the same size and permeability.

6. Compared with iron powder core, iron-silicon-aluminum performs better at high temperatures. In some applications, the use of iron-silicon-aluminum is also smaller than that of iron powder core.

7. It is very suitable to use a ferrosilicon core in the case of a large noise filter inductor that does not need to pass through a large communication voltage. The use of a ferrosilicon core can reduce the size of the in-line filter, since the number of turns required is less than that of ferrite. Iron-silicon-aluminum also has a magnetostriction coefficient of nearly zero, that is, it is very quiet in the audible frequency range of noise or in-line current roughening.

8. High magnetic flux density and low core loss characteristics make the ferrosilicon core suitable for power factor calibration circuits and unidirectional drive applications such as flyback transformers and pulse transformers.

Mirrack (Guangdong) Micro Metal Magnet Tech. Co., Ltd. is a hi-tech company specializing in R&D & manufacturing of high quality alloy powder cores, as well as a solution provider for a variety of magnetics applications. Email: danny@mirrack.com

What are the advantages of sendust cores?

November 29, 2018

Loss Reduction of Output Inductor for Power Supply

December 05, 2018

Cost Reduction of PFC Inductor for Power Supply

December 05, 2018

Noise Resolution of Inductor for Inverter

December 05, 2018