Home / News

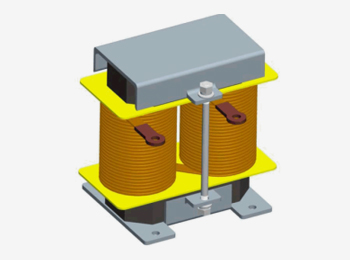

The stray capacitance on the inductor comes from two aspects, one is the capacitance between the windings, and the other is the capacitance between the winding and the core. The turn-to-turn capacitance is related to the winding method and the number of turns of the coil, and the capacitance between the winding and the core is related to the core material. The following Mirrack shares the method of iron silicon aluminum magnetic surround line.

Reducing the stray capacitance of the inductor starts from two aspects. First, if the core is a conductor, the capacitance between the winding and the core should be reduced first. The method of reducing the capacitance between the winding and the core is to add an insulating material with a lower dielectric constant between the winding and the core to increase the distance between the winding and the core. After solving the parasitic capacitance problem between the winding and the core, the inter-turn capacitance can be reduced by the following ferrosilicon-aluminum magnetic wrap method:

1. As far as possible, single-layer winding: When space allows, use a larger core as much as possible, so that the coil can be a single layer, effectively reducing the inter-turn capacitance.

2. Input and output are far away: Regardless of the form of the inductor, the input and output of the coil should be kept away, otherwise the capacitance between the input and output will short the entire inductor.

3. Multi-layer winding method: The number of turns of the coil is large, and when it is necessary to be wound in multiple layers, it is necessary to wrap in one direction, and overlap the sides, and do not wrap around one layer and then rewind.

4. Segmented winding: the coil is wound on a magnetic core, so that the capacitance of each segment is small, and the total parasitic capacitance is the series connection of the parasitic capacitances on the two segments, and the total capacity ratio is the parasitic capacity of each segment. small.

5. Multiple inductors are connected in series: a large inductor can be decomposed into a larger inductor and a small number of inductors with different inductances. By connecting these inductors in series, the bandwidth of the inductor can be expanded.

Mirrack (Guangdong) Micro Metal Magnet Tech. Co., Ltd. is a hi-tech company specializing in R&D & manufacturing of high quality alloy powder cores, as well as a solution provider for a variety of magnetics applications. Email: danny@mirrack.com

What are the advantages of sendust cores?

November 29, 2018

Loss Reduction of Output Inductor for Power Supply

December 05, 2018

Cost Reduction of PFC Inductor for Power Supply

December 05, 2018

Noise Resolution of Inductor for Inverter

December 05, 2018