Home / News

The metal soft magnetic powder core is a soft magnetic material. It is a kind of magnetic core produced by a special process using a powder made of metal or alloy soft magnetic material.

The metal soft magnetic powder core mainly includes four series of iron powder core, iron silicon aluminum magnetic powder core, high flux magnetic powder core and molybdenum magnetic powder core.

Iron cores are magnetic cores produced by dosing, pressing and coating with high-purity iron powder or hydroxy iron powder. Because the production process is simpler than other kinds, the raw materials are the cheapest, and have good magnetic properties, it is the most widely used and widely used in the four series of metal soft magnetic powder cores. From the -2 material iron powder core of μe10 to the iron powder core of various materials such as -26 and -52 of μe75, it is suitable for various occasions. There is also a composite iron powder core which is doped with an appropriate amount of ferrite, and has a high magnetic permeability, and can compensate for the defect of low magnetic permeability of the iron powder core in some applications.

The iron-silica magnetic powder core (sendust cores) is a metal soft magnetic powder core produced from a powder containing an alloy of 5.4% aluminum, 9.6% silicon, and the balance of iron. The iron-silicon-aluminum alloy was invented by the Japanese Zeng Benliang and Yamamoto Hiroshi in the 1930s. The invention was in Sendai County, Japan, so it is also called Sendust alloy, which is a better soft magnetic material. However, since its performance is hard and brittle and cannot be processed, it is far less widely used as a kind of metal soft magnetic material than various permalloys. The iron-silicon-aluminum magnetic powder core began to be used less because of its poor forming properties. Due to the soaring nickel price, the iron-silicon-aluminum magnetic powder core has outstanding performance-price ratio, so that its dosage rapidly exceeds that of the MPP magnetic powder core, and it has become the most widely used and widely used soft magnetic powder core of the three alloy series. Kind. Ee10 ~ μe147 various properties of the iron-silicon-aluminum magnetic powder core, where it can replace the MPP, etc., you can use the iron-silicon-aluminum magnetic powder core. Due to the large increase in demand, it in turn has led to improvements in production process technology and product quality.

High flux cores are produced from powders made of NiFe50 permalloy. The most important feature is high saturation magnetic flux density, up to 1300mT, and permeability from μe10 to μe160. The gear cores have higher saturation values than the other two alloy series. Because of this feature, it also makes it impossible to use it in some applications.

M.P.P cores is a metal soft magnetic powder core produced from Ni81Mo2 permalloy powder. Among the four series of metal soft magnetic powder cores, the comprehensive performance of molybdenum magnetic powder core is the best. Its magnetic permeability can be as high as μe500 or more. It is the typical representative of the most excellent metal soft magnetic powder core. Therefore, it is the first widely used among the three alloy series. Especially in defense, military products and high-tech products, molybdenum magnetic powder cores are required for better materials.

In addition to the above four series of soft magnetic powder cores, the metal soft magnetic powder cores of the iron-silicon series and the amorphous micro-crystal series are gradually being expanded.

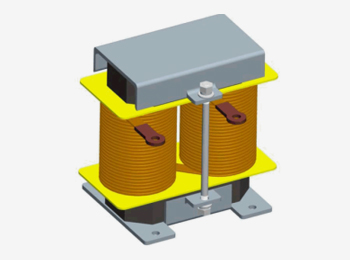

The metal soft magnetic powder core is mainly used as a toroidal magnetic core, and has been generally standardized in size from various common specifications of Φ3.6 to 77.8 mm. The maximum specification of iron powder core is Φ130mm. In order to increase the capacity, a plurality of magnetic cores can be used in a stacked manner. In addition to the toroidal core, various U-shaped and E-shaped metal soft magnetic powder cores have formed standardized and standardized specifications at home and abroad.

Mirrack (Guangdong) Micro Metal Magnet Tech. Co., Ltd. is a hi-tech company specializing in R&D & manufacturing of high quality alloy powder cores, as well as a solution provider for a variety of magnetics applications. Email: danny@mirrack.com

What are the advantages of sendust cores?

November 29, 2018

Loss Reduction of Output Inductor for Power Supply

December 05, 2018

Cost Reduction of PFC Inductor for Power Supply

December 05, 2018

Noise Resolution of Inductor for Inverter

December 05, 2018