Home / News

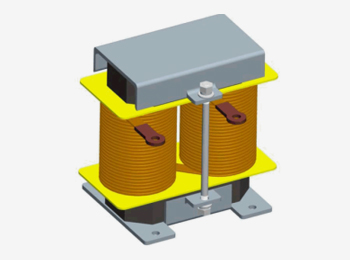

Mirrack talks about how to improve the internal resistance of iron core magnetic ring and reduce iron core magnetic ring iron loss. Ferrite materials have excellent high-frequency characteristics, but they cannot be used as high-power devices because of the low saturation magnetic flux density. The powder magnetic core material has excellent high frequency characteristics and high magnetic flux density, and can be widely used in fields where electrical steel and ferrite cannot be applied. This material is molded from a mold, can be made into a variety of complex shapes, and has the characteristics of workability.

Today, Mirrack takes everyone to learn how to improve the internal resistance of the iron core magnetic ring and reduce the iron loss of the iron core.

The improvement of the iron powder core magnetic ring insulation method, in the insulation treatment process consisting of mixing and drying, in order to completely insulate the iron powder to select the best surfactant, the insulation treatment firstly adds water-soluble insulation treatment to the iron powder. The liquid is mixed with a special mixer. At this time, the difference in the specific resistance can be found in the insulating treatment liquid depending on the type of the surfactant to be added. Selecting the surfactant with the lowest contact angle gives the highest intrinsic resistance, which has been fully verified in the experiment.

When a rust inhibitor is added to the solution, the density and the specific resistance value show the lowest value when no rust inhibitor is added. When the amount of the rust inhibitor added is a certain value, the inherent resistance is the largest and the density is also increased. The above experimental results show that it is effective to form a uniform insulating film layer on the surface of the powder magnetic core by selecting the optimum surfactant and adding the rust inhibitor.

The iron powder core magnetic ring temperature stability, the metal powder used has the same composition as the electromagnetic steel plate, has good temperature stability, and the epoxy resin is also a material with excellent stability. The prepared composite was subjected to a test for 1000 hours in air at 155 ° C, and no deterioration in material properties was observed.

Iron powder core magnetic ring noise, due to the large mechanical damping of the magnetic composite material, the core noise is small, the reactor using the annular ferrite core and the magnetic composite reactor having the same size and inductance When comparing noise characteristics, the noise of a reactor with a magnetic composite material is reduced by about 10 db for a sinusoidal voltage of 500 Hz to 20 kHz.

Mirrack (Guangdong) Micro Metal Magnet Tech. Co., Ltd. is a hi-tech company specializing in R&D & manufacturing of high quality alloy powder cores, as well as a solution provider for a variety of magnetics applications. Email: danny@mirrack.com

What are the advantages of sendust cores?

November 29, 2018

Loss Reduction of Output Inductor for Power Supply

December 05, 2018

Cost Reduction of PFC Inductor for Power Supply

December 05, 2018

Noise Resolution of Inductor for Inverter

December 05, 2018